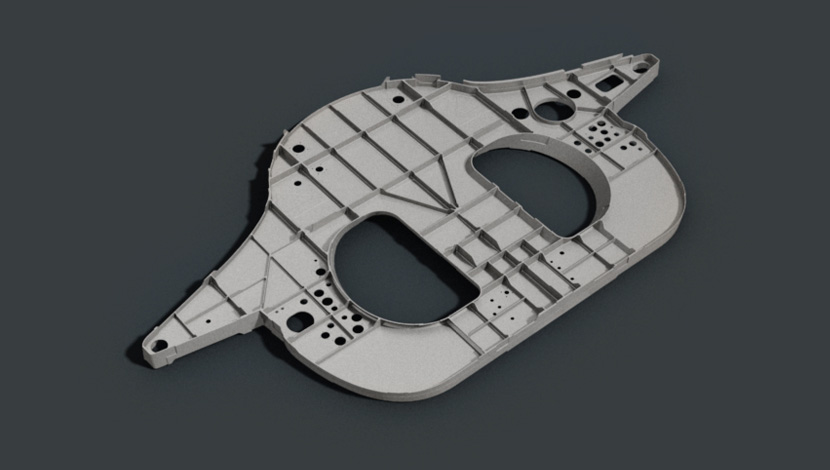

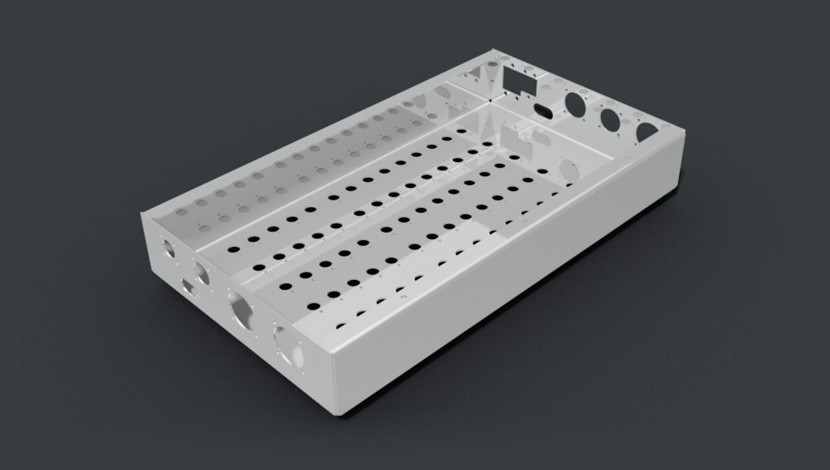

Machining part

We are performing high speed manufacturing and Finishing process for aluminum machining product of aircraft structuring role and deliver the products in perfect quality guaranteed by CMM measurement on time.

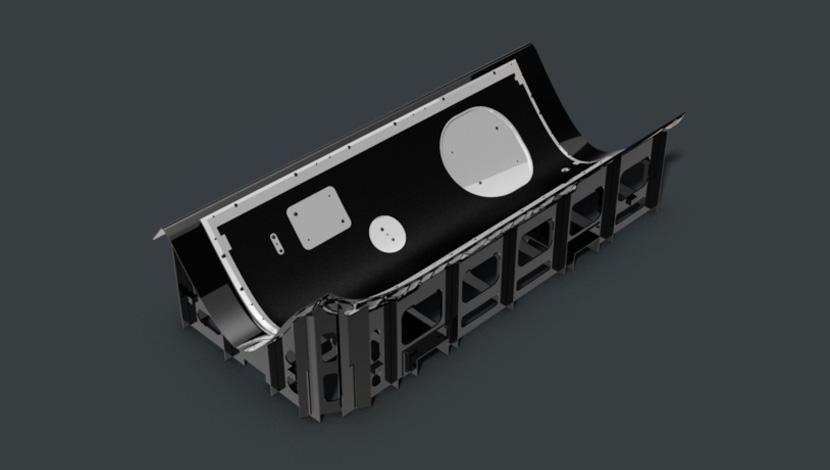

Sheet metal part

We are performing all processes about Sheet metal, extrusion, non-metal part molding and shape machining which are required in aircraft and performing turn-key engineering by a product information of customer from simple shape to complex shape and deliver on time.

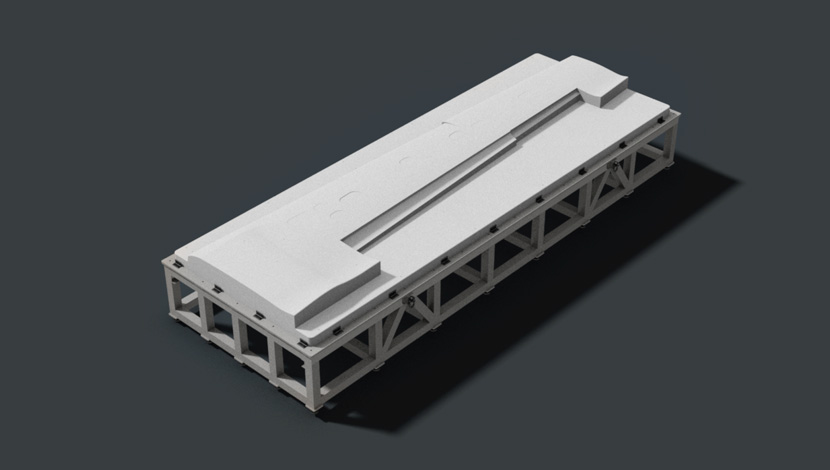

Master tool

Master tool, the tool for managing shape of I&R part and hole, performs controlling function for perfect coordination when you produce or repair the related tool. it is required in part manufacturing and assembling such as outer skin which is predicted to part change, maintenance door or hinge door & glass frame.

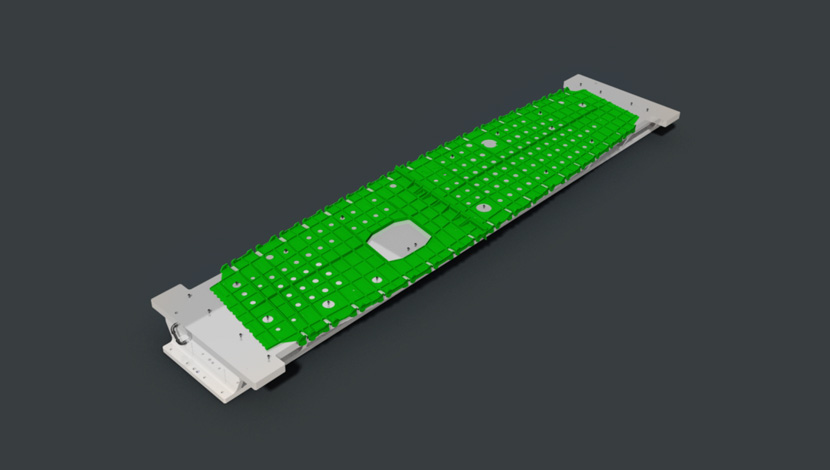

Machining tool

Machining tool, which cannot fix by standard clamping method, is tool to minimize work preparation time such as clamping & set-up considering mass productivity. In general, Aircraft part needs at least 2 machining tools for bifacial process due to decrease the weight, Vacuum clamping will be added if prevention of vibration is necessary.

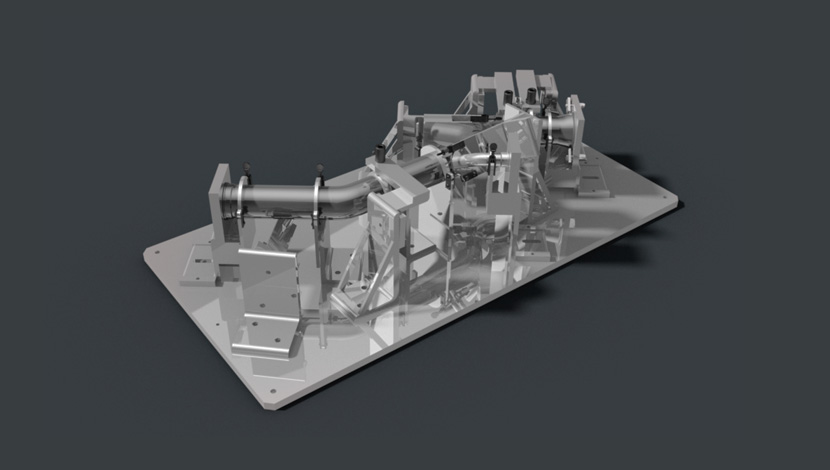

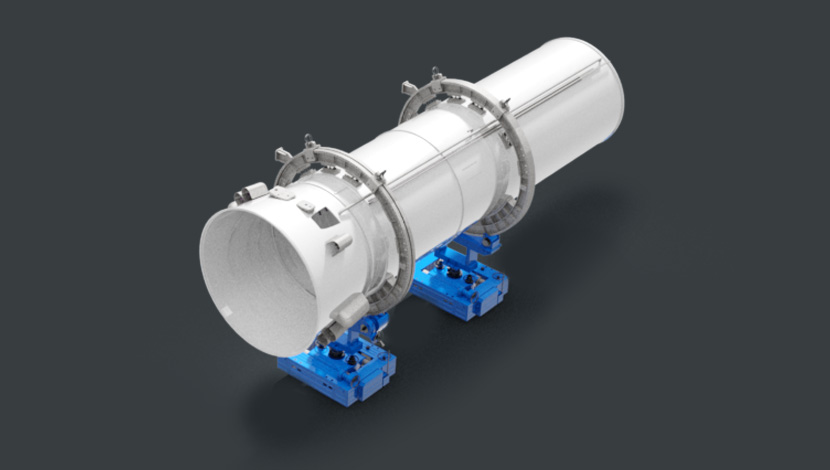

Welding tool

Welding tool, the fixturing for Tuby ass’y welding which is required for aircraft manufacturing. We perform shape test after positioning of 3D Bending tube and welding. In general, Standard locator ass’y is applied but special locator is applied if the installation area is uncomfortably narrow.

Bonding tool

Bonding tool, the fuxturing for lay-up of aircraft composite part and assembly bonding process. We enable the verification of ply pattern and lay-up by laser project equipment. In general, aluminum mold is applied for small project but graphite & invar mold is applied for compount surface for big project.

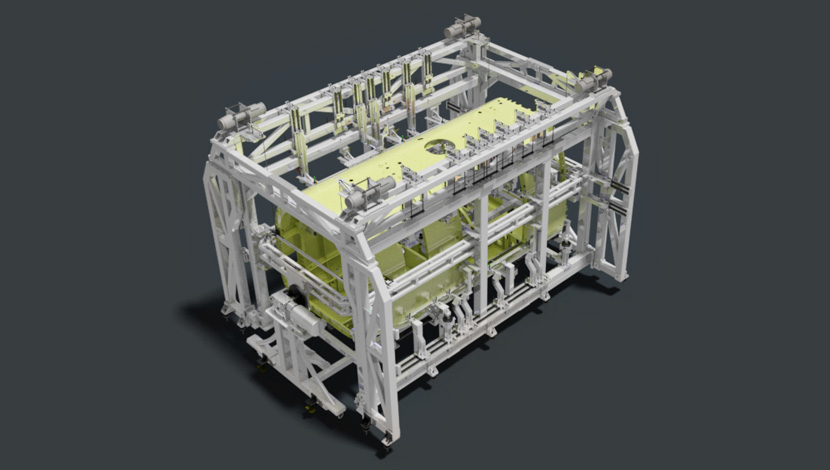

Assembly tool

Assembly tool, the fixturing which is required to sub assembling or final assembling aircraft parts, is separable into several steps. In general, we perform drilling and riveting & fastening after determine assembling positions for direct parts but there are various assembly tools which play indirect roles such as product handling and holding.

Miscellaneous tool

Miscellaneous, the fixturing which plays indirect roles but direct functions for aircraft part and assembling process, is produced for convenience such as transportation / working support. In general, it is made as special shape/function for backing up the fixturing and the process for aircraft manufacturing.

ALL OF TECHNOLOGY

CAPABILITY

Ready for potential customers needs and have been Increasing capability

View Capability >

MANAGEMENT

QUALITY SYSTEM

Quality system complies with aviation international standards

View Quality >

TOOLING

MANUFACTURING

Provide the all of tooling service in aerospace based our development rack record

AEROSPACE

PART MANUFACTURING

Perfect manufacturing process management regarding the Sheet metal, Extrusion & Machining part